At present, in the field of architecture, spacecraft houses occupy a unique position with their innovative design, efficient space utilization, and prefabricated assembly construction methods. Its development trend is good, with continuous improvement in intelligence and environmental performance. Sound insulation and thermal insulation performance are crucial to the living experience. Good sound insulation can isolate external interference, while high-quality insulation can maintain comfortable temperatures and save energy and reduce consumption. However, there is still room for improvement in related performance, so it is necessary to use material innovation and other means to enhance sound insulation and thermal insulation effects, and promote their sustainable development.

Sound insulation characteristics of cabin materials

The outer shell of the spacecraft housing is made of 2.0 space aluminum plate, which is not only lightweight in texture, but also has good sound insulation performance. Its surface is coated with fluorocarbon baking paint to make it appear more capable, and the smooth surface can effectively reflect sound waves and reduce sound penetration. The internal steel structure is composed of high-strength galvanized steel pipes, making the entire cabin more solid and capable of achieving excellent seismic resistance of level 10 and wind resistance of level 12. At the same time, it also plays a certain auxiliary role in sound insulation. The interior decorative wall panels are made of carbon crystal panels, which have high-density structure and damping characteristics. High density hinders the propagation of sound, while damping properties can convert the mechanical energy of sound vibration into thermal energy for dissipation, further enhancing the sound insulation effect inside the cabin.

Application of soundproof filling materials

Polyurethane foam: polyurethane foam can effectively prevent sound transmission because of its closed cell structure. And the entire compartment of the spacecraft is filled with it, which significantly improves the sound insulation effect, generally increasing the sound insulation effect by more than 10 decibels. Especially its ability to absorb low-frequency noise such as footsteps is extremely outstanding, which creates a quiet resting environment for residents.

Rock wool: Rock wool, as an inorganic fiber material, has a good absorption effect on mid to low frequency sound. In some wild environments, it can effectively block noise such as wild animal calls from entering the cabin.

Structural design optimization for sound insulation

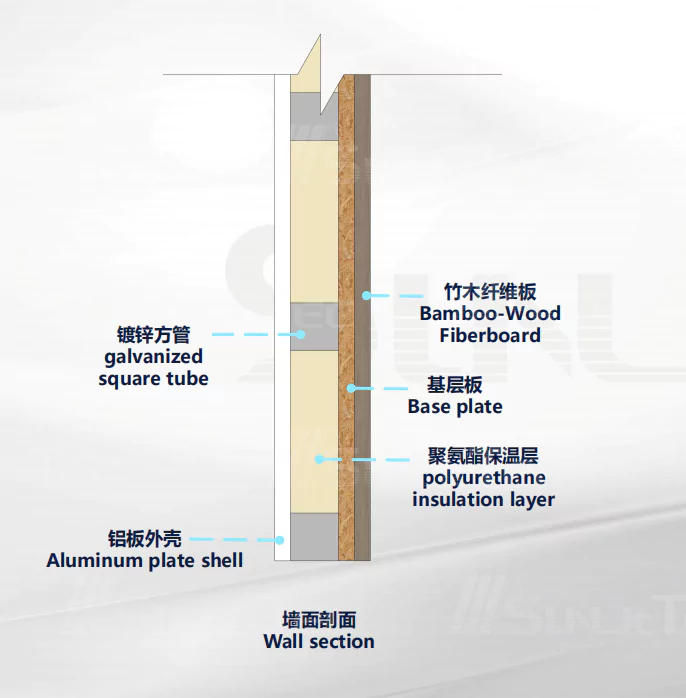

Double layer structure design: The walls of the spacecraft house adopt a multi-layer structure design, and the outer shell is made of 2.0 space aluminum plate. Polyurethane is filled between the outer shell and the steel structure keel as an insulation layer, with European pine board as the base layer, and carbon crystal board as the external decorative surface. This multi-layer structure can first block the propagation of sound, thereby achieving sound insulation effect.

Sealing structure treatment: The cabin door is equipped with multiple layers of sealing strips, and the large-area glass structure adopts double-layer or three-layer insulated glass, and is matched with high-quality sealing glue. These sealing measures greatly enhance the sound insulation performance of the entire cabin.

Thermal insulation performance improvement technology

Wall materials with superior thermal insulation performance

Polyurethane sandwich panel is a commonly used wall material for spacecraft housing, with extremely low thermal conductivity, which can effectively prevent heat transfer. In the hot summer, the temperature inside the spacecraft using polyurethane sandwich panels can be 5-8 ℃ lower than the outside, providing a cool indoor environment for residents.

High performance door and window glass

Reasonable cabin shape

The spacecraft housing adopts a streamlined cabin shape design. This shape is not only aesthetically pleasing and technologically advanced, but also has advantages in terms of insulation. The streamlined design can reduce the surface area of the cabin, decrease the heat exchange area, and thus help maintain stable temperature inside the cabin.

Application of Thermal Insulation Bridge Breaking Technology

Install insulation bridges in metal frames and other areas to cut off heat transfer pathways. Through this technology, heat loss can be reduced by 15% -20%, further improving the insulation performance of the spacecraft housing.

Comprehensive control system auxiliary performance improvement

intelligent temperature control system

The spacecraft is equipped with variable frequency air conditioning, which can intelligently adjust the compressor speed to achieve energy-saving operation. The intelligent control system can also zone temperature control according to the needs of different areas, and automatically adjust the operating mode based on environmental parameters to ensure that the cabin always maintains a comfortable temperature.

Auxiliary heating and ventilation system

In cold weather, auxiliary heating devices such as electric heaters can quickly increase the temperature inside the cabin. The ventilation system plays an important role in summer by introducing cool outdoor air, expelling hot air from the cabin, and achieving efficient ventilation and air exchange through intelligent control.

Conclusion

The spacecraft housing has achieved significant improvements in sound insulation, thermal insulation, and other performance through various advanced technologies. From the selection of cabin materials, application of sound insulation filling materials, optimization of structural design, to high-performance door and window glass, reasonable cabin shape, and insulation bridge technology, coupled with the assistance of a comprehensive control system, a quiet and comfortable living space has been created for residents. With the continuous advancement of technology, future spacecraft houses are expected to further improve in terms of sound insulation, thermal insulation and other performance, and their application prospects will also be broader, bringing more innovation and choices to people’s living styles.

Do you think my descriptions of each part of the technology are clear? If you want to add some specific technical details or have more accurate requirements for the effect data of certain technologies, feel free to let me know at any time.